If you are in an industry that lifts loads, then it's likely that you've heard of webbing and wire rope slings. As great as these items are, have you ever asked the question what is the difference? Or why might I buy one sling over another?

Well if you have you're in luck as this article is going to outline the key differences and give recommendations for when to use the two different variations that we're discussing.

If at any point in this article you have any questions or want to discuss what the best product is for your situation, please contact a member of the LES USA team who will be happy to help you.

Let's start by giving a bit of background on these products by asking the key question: what are they?

WHAT ARE WEBBING SLINGS?

In our article, ‘6 Ways You Can Use Webbing Slings,’ you will find out that webbing slings are useful for lifting loads or items that could be fragile or damaged if done with a metal structure such as a chain sling or wire rope sling.

Taking the description from that article, this product is made of soft polyester and is lightweight which makes them ideal for fragile loads since they aren’t abrasive.

However, it's important to note that this does not mean other variations are not useful in other lifting situations - they're durable and versatile making them great for various applications.

To get a full breakdown of what this handy piece of equipment is, you can check out the article ‘What are webbing slings and how they can help your company’ where you'll get an in-depth view on how this particular product can be the right solution for you.

WHAT ARE WIRE ROPE SLINGS?

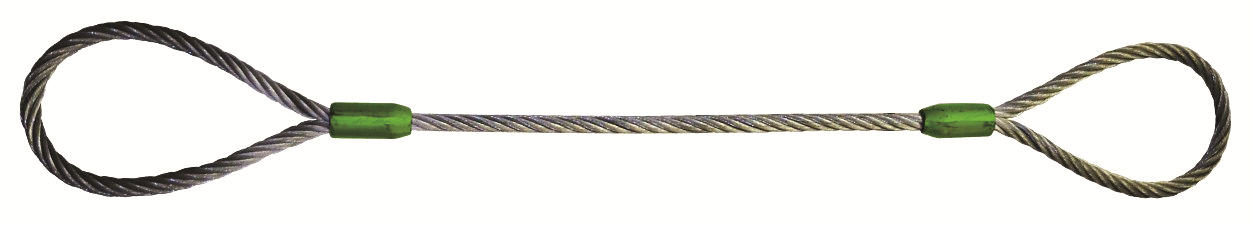

These types of slings are different in the fact that they are strands of metal twisted together to act as a harness to lift various goods. You can expect these slings to be strong and durable while having various uses across several industries.

It's likely you'll find them being used in industries that include mining, oil, gas, construction, and marine.

The great aspect of this piece of equipment is that they come in a range of configurations and sizes to give you support with any lifting you might need to do.

There are a variety of different types available such as Nine-part Slings, Bridle Slings, Eye & Eye Slings, and Multi-part.

You can read the article ‘Facts about wire rope slings for heavy loads’ where you get a full breakdown of facts and consideration points when using these slings for lifting.

WHEN CAN YOU USE WIRE ROPE SLINGS INSTEAD OF WEBBING SLINGS?

Choosing the right type of lifting sling can be dependent on you having a complete understanding of the piece of equipment and the environment in which it is being used. You also have to consider if you need a sling that is flexible to fit over the load.

Webbing slings are useful when lifting an item that you either do not want to scratch or for items that need a sling that can flexibly mold around them. Finding a product that beats the flexibility and strength of these slings will be a tough one as they are known for being robust and effective. These slings are popular in the rigging industry due to being inexpensive and being available in many sizes which allow them to fit around larger loads.

Webbing slings have various advantages, however, this doesn't mean they are the right fit for all lifting applications and you need to consider what they will be doing before purchasing.

They have relatively low heat resistance meaning they are not as durable as steel slings since steel is not abrasive and is cut resistant. These types of slings are unable to have endpoints attached meaning there are limited in the directions they can help you when lifting loads.

If you speak with someone who is familiar with the differences (such as the team at LES USA) you will find that wire rope slings can be the preferred lifting device. This is due to their multiple steel wires that lay in a helical pattern which provide strength, flexibility, and the ability to handle stress when lifting.

BENEFITS OF USING ONE OVER THE OTHER

BENEFITS OF USING ONE OVER THE OTHER

The specific material of your sling plays a vital role in determining the benefits the product will have for either your company or personal lifting situations.

That's why we wanted to put together a number of benefits of how they can support you, both for your business and team as well as for your personal use.

You will find that a standard wire rope sling has between 1-4 legs depending on the version you get and the weight and size of the item you wish to lift. Additionally, you can add various end types or endpoints such as swivel slings hooks and self-locking hooks.

We encourage you to please check out our full range of endpoints to get more details and see if this is an add-on that would benefit you.

It's important to remember that the hardware, including the hooks and the master links, can be reused if the rest of the item suffers damage. A key benefit of this sling is the rope is made of wider individual wires which will have less abrasion and resistance when lifting making them stronger, resistant, and able to withstand heavier loads.

These slings are designed to have a 5:1 ratio. This means the breaking strength of the sling is five times higher than the working load limit (WLL). Please remember to store and look after your gear in order for them to work at their optimum.

Also, another key advantage for any industry is the fact wire rope slings have a lower initial cost than alloy chain slings. This means in the long run, if you keep them in good condition, you will be able to use them for many years before you will have to replace them.

CAN THESE SLINGS HELP YOUR SITUATION?

As we've discussed the above points together, you can hopefully get an idea of how there are various benefits these different types of slings can bring to your lifting situation, whether in a commercial or personal environment.

What we haven't done is look at how these slings can help your specific situation or be bundled with our other products to provide you with an effective solution. If you're unsure about anything above or want to get more information for your specific situation, please contact a member of our regularly trained LES USA team who will be happy to assist you.