Free-standing cranes, also known as workstation cranes, offer ergonomic solutions for lifting heavy objects in facilities that otherwise can’t support ceiling or wall-mounted versions.

There are two main types of this product: jib and bridge, both of which we're going to give a look at in this article.

These two types of systems offer different advantages and are used in different types of facilities for various applications. So it's important you know the difference before handing over your cash and purchasing one.

In this article, we will discuss the basics of each type of system listed above, the advantages of using one over the other, and how to choose the right system for your business needs.

If by the end of this article you think your business would benefit from one of these products, please get in touch with a member of the Lifting Equipment Store USA (LES USA) team where they will be happy to discuss your needs.

WHAT ARE FREE-STANDING AND WORKSTATION JIB CRANES?

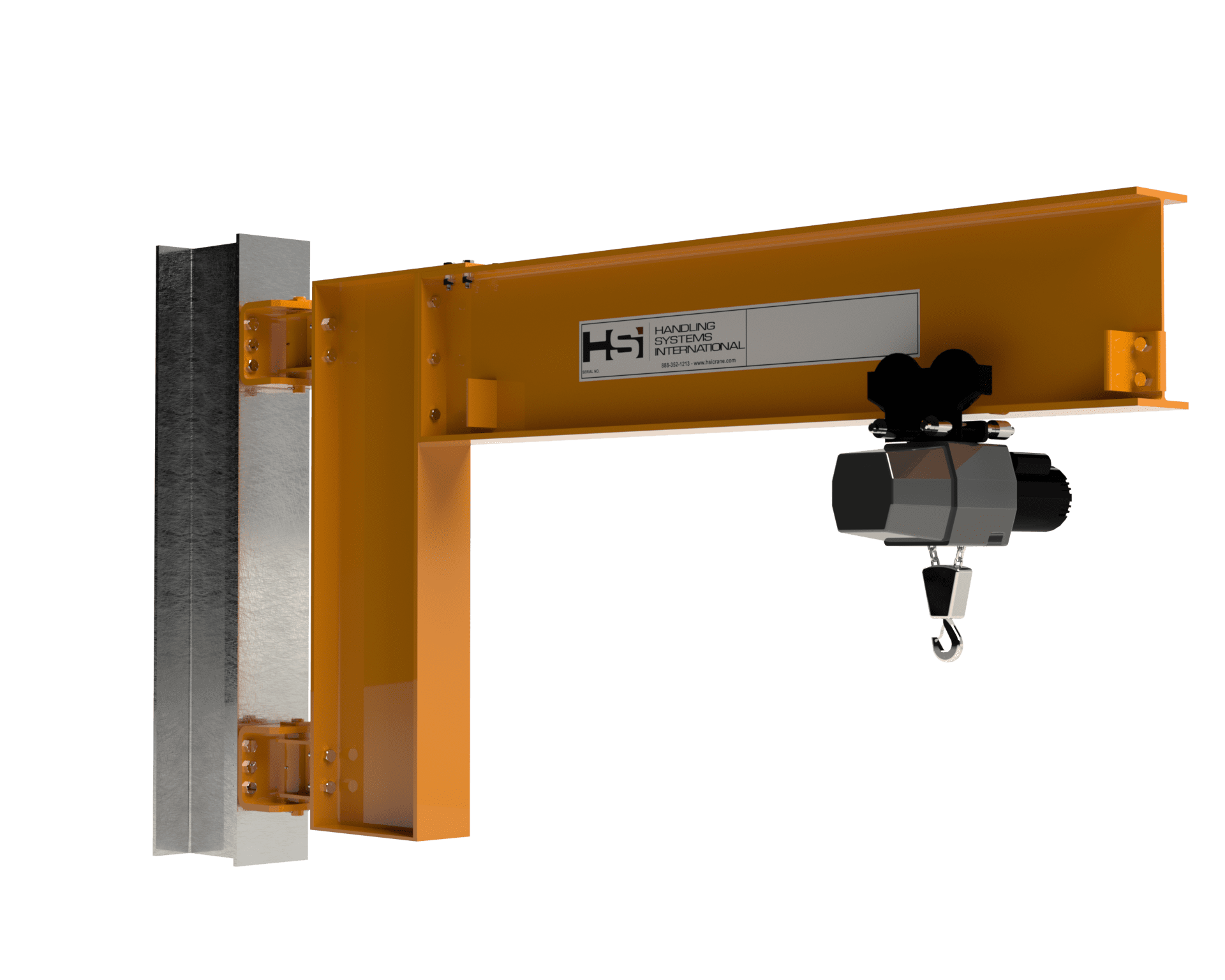

The one with an I-beam is the most popular type of jib because it can be installed for indoor or outdoor usage. They are also great substitutions for heavier, traditional I-beam jibs.

You can place these systems in open areas to support individual work cells or can be placed underneath a larger bridge system.

The jib systems are often used at marinas and loading docks due to their ability for outdoor usage. Indoors, multiple jibs can be used for staged operations in machining and assembly facilities.

Jib systems consist of a hoist attached to a trolley that moves up and down the boom (also known as the reach, or the arm). On the free-standing version, the boom can achieve up to a 360° rotation, which is helpful for individual workers who need to lift loads within their own work cells. The length of the boom can also vary depending on your needs.

This product is mounted and installed by using one of three designs:

BASE-PLATE MOUNTED

This is the easiest way to install a free-standing version and by far the most popular design. The mast, or pillar, is secured by bolting a base plate onto a foundation of reinforced concrete and then using gussets to reinforce the mast.

FOUNDATION-INSERT MOUNTED

A welded steel plate is positioned at the bottom of the mast, which is then anchored during the first-pour concrete footing. The need for gussets is eliminated with a second concrete pour that supports the mast.

SLEEVE-INSERT MOUNTED

A sleeve is anchored to a welded steel plate during the first-pour concrete footing. The mast is inserted into the sleeve, which is supported by a second pour and is then welded into place. The design allows you to relocate the system without damaging the mast, however, these are not the easiest to move.

Workstation versions are another type of free-standing jib. They are much more ergonomic than the I-Beam Jibs, however, workstation jibs have a lower lifting capacity (500lbs).

In comparison to other jib systems, I-Beam jibs provide the highest capacities, the greatest amount of rotation, and the longest spans; however, free-standing jibs are the most expensive and permanent setups due to the special foundation required for anchoring and securing it and supporting the load during a lift.

Benefits you can get from using this type:

- Spans up to 50’

- Capacities up to 15 tons

- Rotates 360°

- Boom heights up to 40’

- Varying boom lengths

- Can use outdoors

WHAT ARE FREE-STANDING WORKSTATION BRIDGE CRANES?

What is also known as a workstation bridge crane, it's an ergonomic solution for facilities where repetitive lifting is required but where installing an overhead version would be impractical.

This is a type of overhead heavy lifting system that works differently compared to other overhead systems you might find.

They consist of a pair of runway beams connected by a single or double beam configuration known as the “bridge.” An end truck supports the bridge, which moves and up down the bay using wheels.

This version can use multiple bridges to help workers maneuver heavy objects by moving back and forth covering a rectangular area. Their versatility makes them popular for various applications including welding, assembly, and fabrication.

They are mounted to the floor and all of the connections are bolted together rather than welded, which allows the system to be easily dismantled and moved from one location to another – perfect for usage in leased buildings or buildings that could not otherwise support a ceiling or wall-mounted version.

These are cost-efficient for your business due to their economic design and low power consumption. They are highly effective solutions when you need overhead coverage for areas up to 40-feet wide with an unlimited length. Interconnected parallel systems allow you to cover an entire building if needed.

Benefits you can get from using:

- Spans up to 40’

- Capacities up to 2 tons

- Easy to install

- Easy to dismantle

- Easy to relocate

WORKSTATION JIB VS. WORKSTATION BRIDGE

Well to start with, we want to highlight that both versions are ergonomic and perfect for transferring repetitive loads. The word “workstation” refers to the fact that these two systems use the same enclosed trussed track profile; however, the overall functionality and capabilities of the two do differ with one likely being more effective than the other depending on the task you have at hand.

Workstation jibs are not capable of lifting as heavy a load as the workstation bridge or free-standing I-Beam jibs because the top tube that sits above the shaft of a workstation jib bears most of the weight.

Workstation bridge versions also have a much higher track depth, which makes them sturdier for heavy loads and capable of greater spans.

Workstation jib version is better suited for applications that require fast lifting and transferring of lightweight and repetitive loads.

Workstation bridge cranes are better suited for applications that require fast lifting and transferring of heavyweight, repetitive loads.

FACTORS TO CONSIDER WHEN CHOOSING ONE OVER THE OTHER

Before taking the leap to purchase one, ask yourself these questions to make sure you’re buying the correct product for your specific lifting applications. By asking yourself these questions, you will increase the likeliness that you've got the right equipment for your business.

WHAT IS THE SIZE AND SHAPE OF THE COVERAGE AREA?

The coverage area of free-standing and workstation types is circular while the coverage area of a workstation bridge crane is square or rectangular. It's important that you measure and know the coverage area you are expecting the two different pieces of equipment to cover if you want it to provide the right solution for your business challenge.

MANUAL OR MOTORIZED?

If a manual bridge or boom movement may be unsafe or inefficient in your facility, you can consider motorized rotation. It's always important to check with your supplier whether it is safe for a manual or motorized type to be used within your facility. LES USA is always on hand to discuss your bespoke measurements and what is the correct solution for your business.

DO YOU NEED A PERMANENT OR IMPERMANENT STRUCTURE?

If you are leasing a building or may need to relocate it to another location in the future, a workstation bridge crane can be an ideal solution for you.

WHAT IS THE LOAD CAPACITY?

Workstation jibs have higher load capacity; however, a workstation bridge can be more economical if you’re lifting under 2 tons. It's important to consider and understand what load capacity you need when reviewing which one you need to get.

WHERE WILL IT BE USED?

As you might have guessed, they are fantastic for lifting applications outdoors.

SO, ARE YOU NEEDING ONE?

So we now know what the benefits are to each of the different versions are and how one might be more suitable for your business than the other. At LES USA we have a selection of free-standing types under this category of product that can benefit your business.

If you've got questions on how this product can help your business, please don't hesitate to contact an experienced member of the LES USA team where we can help you choose the variation most suited for your business needs.