When lifting and moving heavy objects, selecting the right type of rigging equipment to use is of utmost importance. Many different types are available, but knowing which type is required depends on the specific application.

Every job requiring these types of goods is different and will likely require a combination of different systems. Having professional riggers on hand will ensure your lift goes safely and smoothly, but it’s always a great idea to be familiar with the different types available to you.

In this article, we will give you an overview of what this piece of equipment is and what the different types are with the goal to help you understand the options available to help your business excel.

If by the end of this article you have more questions about how this type of gear can help you, please

contact Lifting Equipment Store USA (LES USA) where an experienced member of the team will be happy to assist you and discuss in detail the solutions that are available to you.

AN OVERVIEW OF RIGGING

In the construction industry, the word can be used to refer to both the action and preparation of moving heavy objects and the equipment used to do so. The process can be customized to accommodate the needs of each site and load.

Most jobs under this category of work will require experienced professionals (known as riggers) to design and install the correct systems. Riggers will know which equipment is required for specific lifting applications and how best to use them to avoid accidents or injuries.

A plethora of different equipment and hardware are available and using any combination of them together will provide different advantages and disadvantages to your particular application, no matter how small or complex the project at hand might be. Let’s take a look at some of the most common ones and the factors you should consider when choosing the right type of each.

RIGGING HOOKS

These hooks are designed to eliminate slippage when lifting heavy objects. They are typically made of forged alloy steel and come in different designs and styles for different lifting applications. These hooks are categorized based on the size of the hook’s opening, also known as the throat, and sizes range from 5/8” to 1 17/32”. Examples of different types of these hooks include eye, sorting, choker, and clevis grab.

Factors to consider when choosing a hook:

- Total weight of the load

- Material being lifted

- Type of sling to be used

- Angle of the sling

- Sling hitch to be used

- Connection to the load (shackles, eye bolts, etc.)

- Distance between lifting points

EYEBOLTS AND STEEL NUTS

Eyebolts are used as anchor points in rigging configurations. They are commonly used for cables, ropes, and wires, and need to be strong enough to accommodate the required load. Eyebolts come in a variety of materials and sizes depending on the different types and sizes of the loads they will be used for. The two most common types of eye bolts are straight eye bolts and shoulder eye bolts. Straight eye bolts are made for straight line applications, and shoulder eye bolts are made for angular connections. Screw eyes bolts, U-bolts, and lag eye screw bolts are other types of eye bolts.

Steel nuts are used in conjunction with eye bolts and are usually made of 316 stainless steel. The size of the nut to be used depends on the weight, shape, and specifications of the load. Commonly used steel nuts for this type of work include hex nuts, wing nuts, lifting eye nuts, dome nuts and ball ends.

- Factors to consider when choosing an eye bolt:

- Total weight of the load

- Nature of the load

- The material that the eye bolt will be inserted into

- Angle of the load

- Angle of the sling(s)

- Type(s) to be used

PULLEYS AND LIFTING BLOCKS

Lifting blocks and pulleys are used to mitigate the weight of very heavy loads and to simplify the process of maneuvering. Different types of blocks include tilt-up blocks, logging blocks, swivel blocks, square blocks, and the most common type of block: snatch blocks. Lifting blocks come in a variety of sizes and can carry loads up to 30 tons. It's important that you check what you need your lifting block and pulley to do and what weight you need it to lift.

Pulley systems are used in conjunction with rigging ropes that circle the puller and are hooked onto heavy objects for lifting. Pulleys are available in single or double types and vary based on the rope, frame, and sheave size. Synthetic rope is used with pulleys, while wire rope is used with lifting blocks because lifting blocks are used for heavier loads, which wire rope is better equipped to handle.

Factors you can consider when choosing a pulley or lifting block

- Total weight of the load

- Type of rope to be used

- Size of the rope, frame, and sheave

SHACKLES

Shackles are connecting links that can quickly connect and disconnect different types of equipment from each other. Any load that exceeds 6,000lbs may require the use of shackles, which can accommodate up to 11,000lbs.

Anchor and chain are two categories of shackles, but both categories can include different types of shackles: safety, round pin, and screw pin.

Shackles usually involve a steel loop that is closed off with a type of pin, which secures the connection between the holding frame and the supporting material while moving heavy objects. You can get your hands on a variety of shackles with the sizes available ranging from 3/16” to 2 ½”.

FACTORS YOU CAN CONSIDER WHEN CHOOSING A SHACKLE:

- Total weight of the load

- Type(s) to be used

- Sling hitch to be used

- Angle

SYNTHETIC SLINGS

These are used in conjunction with wire ropes to move heavy objects.

These are used in conjunction with wire ropes to move heavy objects.

You will find that they are available in two types: endless and eye-and-eye versions. The endless version is a loop of synthetic material, while the eye-and-eye version feature triangular, flat, or twisted ends that can be made of metal or synthetic material.

The purpose of this type of supportive gear is to help you balance rigging jobs and add extra strength when lifting heavy loads. You can give our

blog on synthetic slings a read to learn more about the different types and their advantages.

FACTORS YOU CAN CONSIDER WHEN CHOOSING A SYNTHETIC SLING:

- Strength and rated capacity

- Weight

- Flexibility

- Resistance to extreme temperatures

- Resistance to tears and abrasions

- Resistance to environmental properties

- Easy inspection of the sling

- Ability to be repaired or not

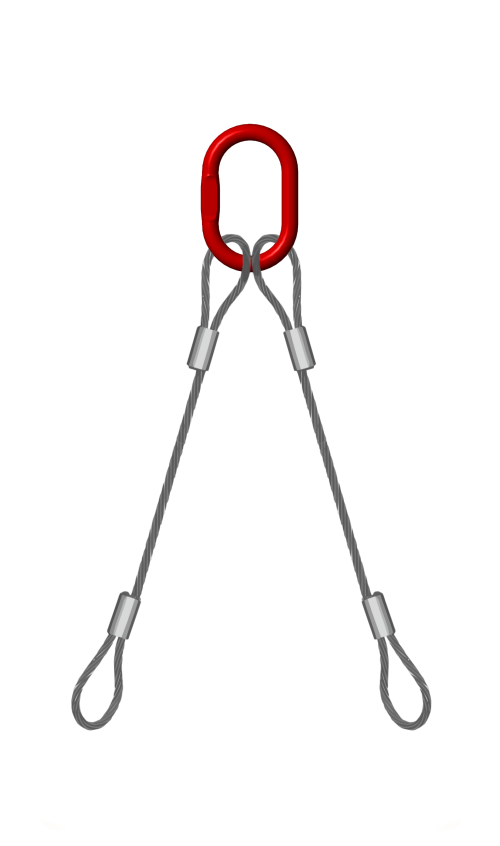

WIRE ROPES AND ACCESSORIES

You can use wire ropes and slings for lifting larger objects. Wire ropes are commonly fortified by multiple strands of carbon steel or stainless steel arranged in a helical pattern for extra strength. Your wire ropes can be galvanized or coated to protect it from certain environmental properties.

They come in multiple sizes, the most common being 6x19 and 6x36, and are available to you in a variety of specifications. Common accessories that are used in conjunction with them are clips, stops, sleeves, and thimbles.

It's important to consider the below factors when you're purchasing wire rope as you want to make sure you've got the correct one for the job. If you don't get the correct wire rope, it can end up adding extra costs for you and possible health and safety risks.

- Strength

- Flexibility

- Resistance to abrasions

- Resistance to crushing

- Resistance to fatigue

- Resistance to corrosion

- Resistance to rotation

DOES YOUR BUSINESS NEED RIGGING EQUIPMENT?

We've now gone through what this equipment is and the various goods you can get from this category together. You should now have a good understanding if it's something that can help your business or not.

These are used in conjunction with wire ropes to move heavy objects.

These are used in conjunction with wire ropes to move heavy objects.